Technical Information

Reducing valves

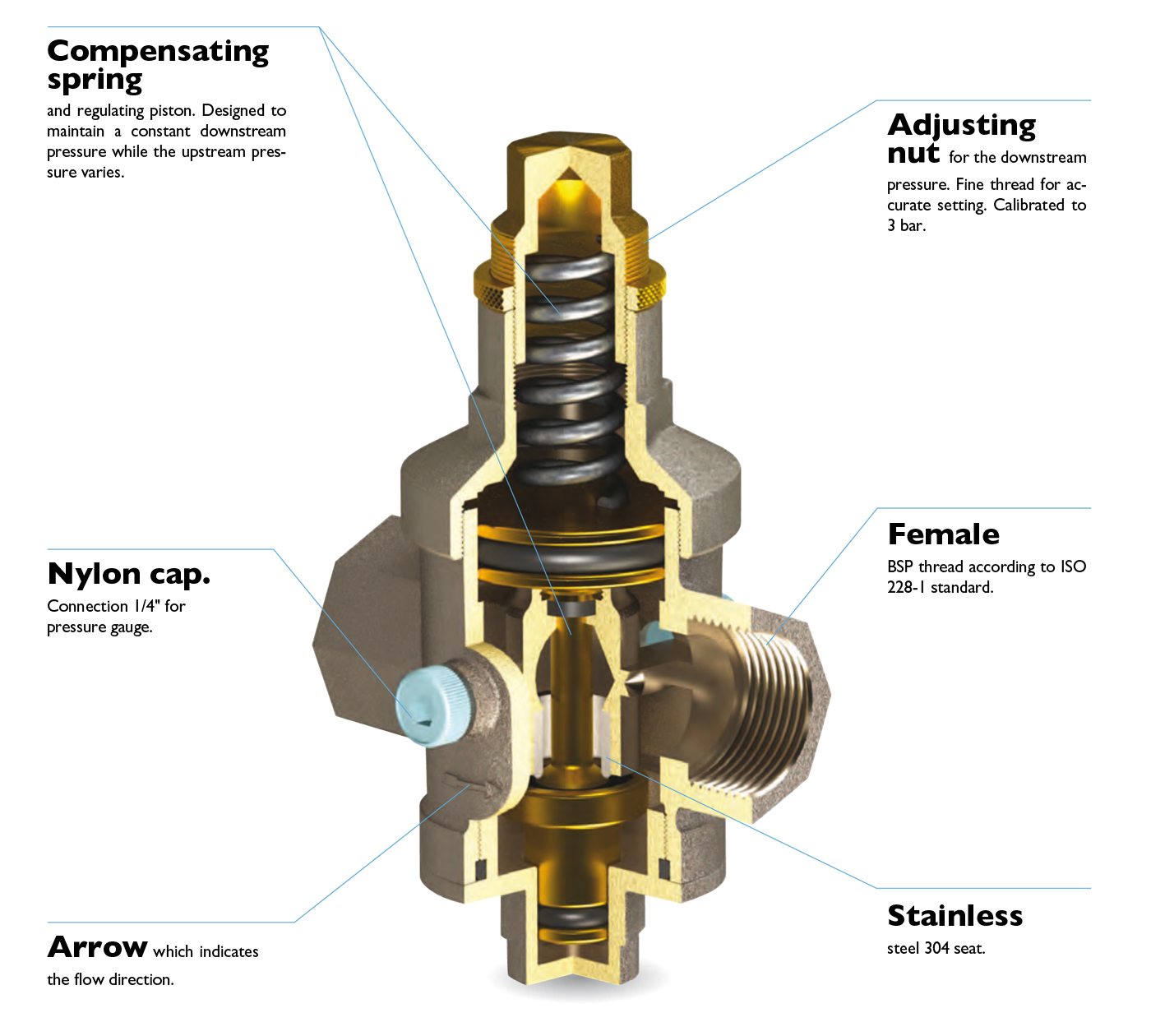

PISTON OPERATED PRESSURE REDUCING VALVES

| ISO 228-1 | |

| 0 °C + 80 / + 120 °C |

|

|

USE

Water, drinking water, Hvac systems, non-aggressive fluids

Vertical or horizontal MOUNTING

ARROW on the body for the flow direction

DISMANTLING possible for maintenance

ADJUSTABLE PRESSURE (factory setting to 3 bar)

STABILISER FUNCTION:

When the upstream pressure changes, the downstream pressure only changes by 8% of the variation (e.g: upstream +5 bar → downstream +0.4 bar). The effect is negligible for the user

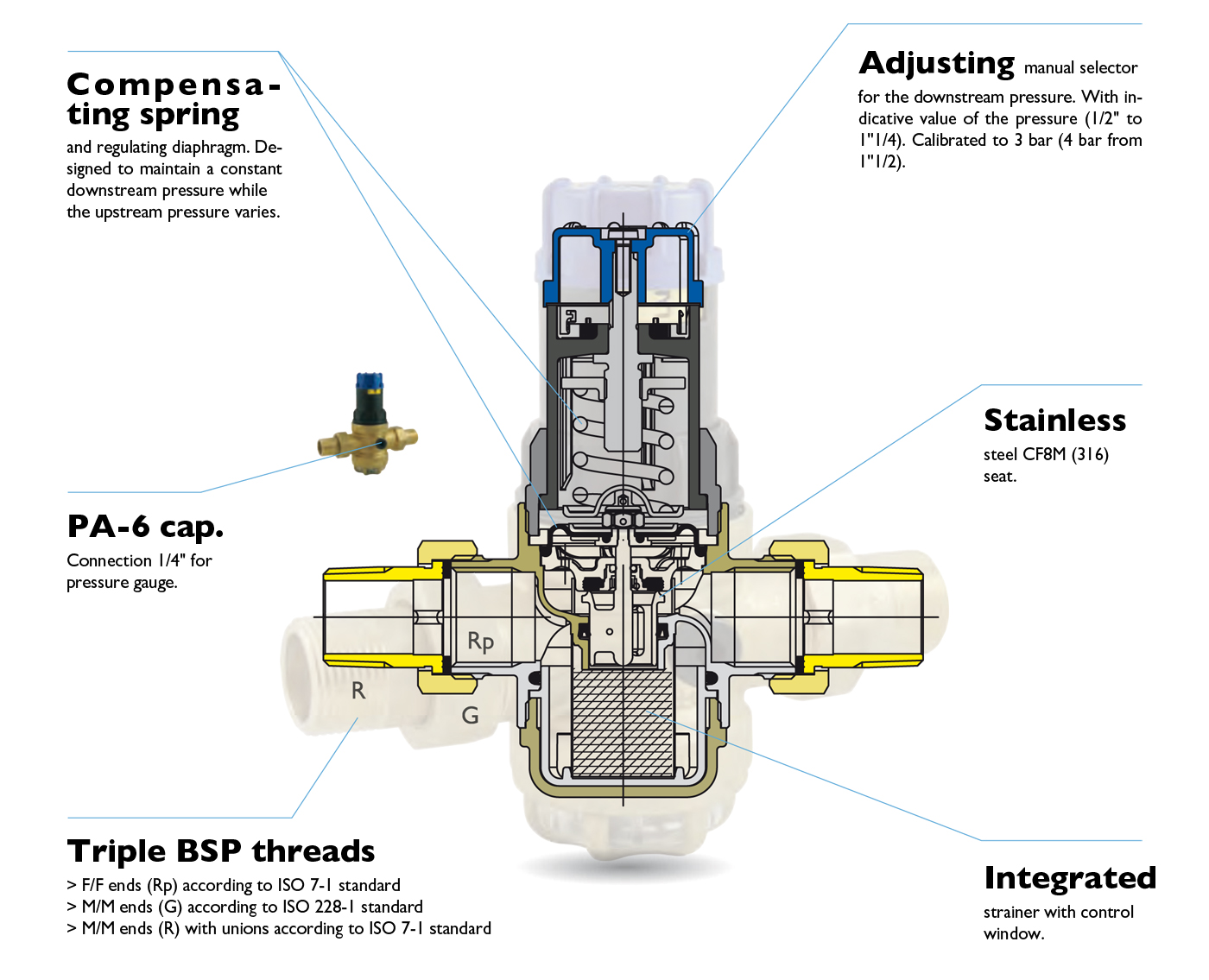

DIAPHRAGM PRESSURE REDUCING VALVES

| MM ISO 7-1 (R/Rp) Union (G) ISO 228-1 |

|

| - 10 °C + 70 °C |

USE

Water, Hvac systems, non-aggressive fluids

Vertical or horizontal MOUNTING

ARROW on the body for the flow direction

DISMANTLING possible for maintenance

ADJUSTABLE PRESSURE (factory setting to 3 or 4 bar)

PRESSURE stabiliser

Water meters

MID WATER METER MARKING

Pressure gauges

CODITAL PRESSURE GAUGES - EN 837-1 STANDARD

|

PACKING Individual box |

PRODUCT designed, manufactured and controlled according to EN 837-1 standard

100% inspection with 5 measuring points

Accuracy class 1.6 (±1.6% of the measuring range)

Brass mechanism with copper

Bourdon pipe

All measuring ranges available from -1 to 1000 bar

Axial or radial brass connection with BSPP male thread (ISO 228-1)

Silicon filled stainless steel 304 cases. Suitable for applications subject to vibrations or humid environments (condensation).

USE

Fluids : All compatible fluids with brass and copier. Except high viscosity or crystallising fluids / Hazardous substances or substances subject to a special regulation (e.g.: oxygen, gas, combustible, toxic agents, …).

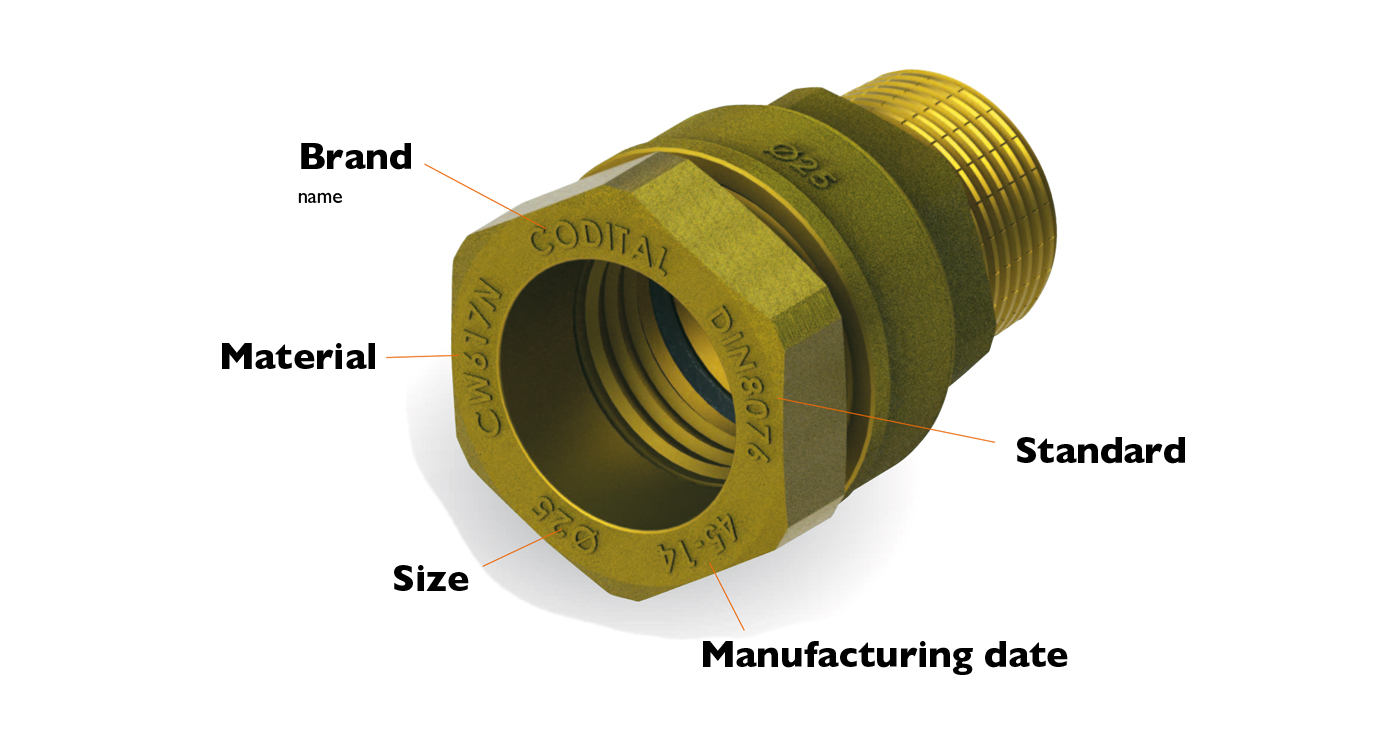

7000 serie

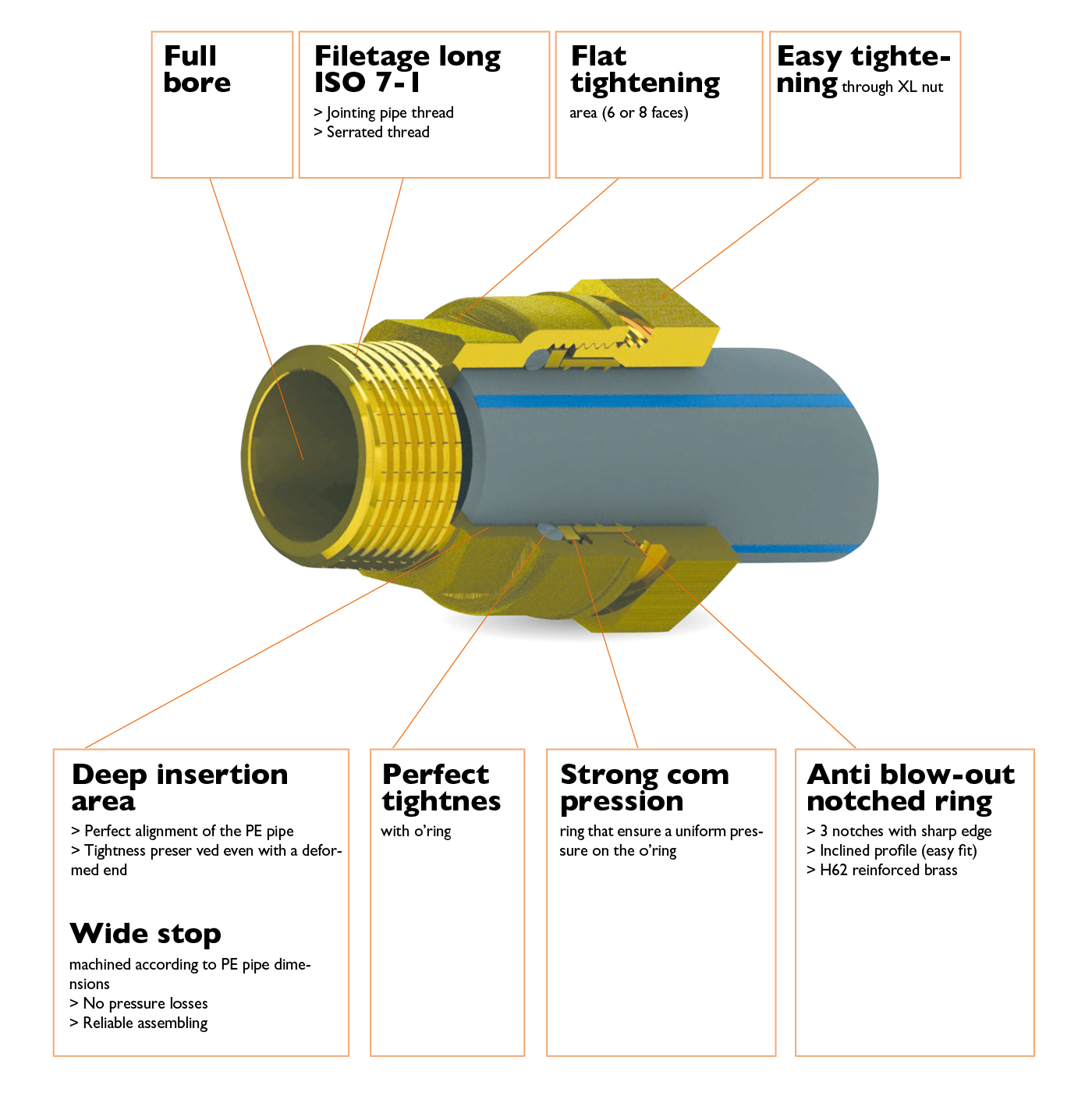

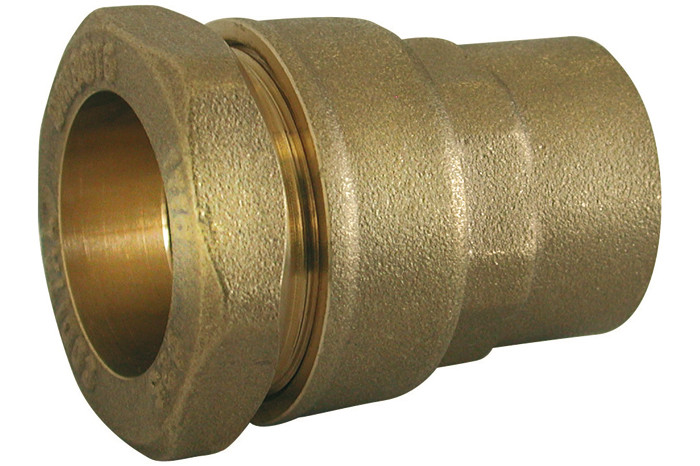

In the last 25 years, the "7000 Classic" series has become an essential reference in the Drinking Water Supply market for its quality, reliability and evolution in order to meet increasingly stringent technical requirements. Designed by the engineers of our design office, the "7000 Classic" series guarantees traceability, longevity and ease of assembly, as well as respect for the environment, health and compliance with European standards.

USE

Drinking water supply, irrigation and watering

DESIGN

DIN 8076 standard

MATERIAL

Forged CW617N brass body and nut

CW617N compression ring

H62 brass notched ring

NBR or EPDM o’ring

Stainless steel 304 bolt (from DN75)

| Thread ISO 7-1 male conical "R" / female parallel "Rp" |

|

| 0 °C / + 70 °C | |

| PN 25 Ø 16 au Ø 63 PN 16 Ø 75 au Ø 90 |

|

|

Marking for a complete identification and traceability

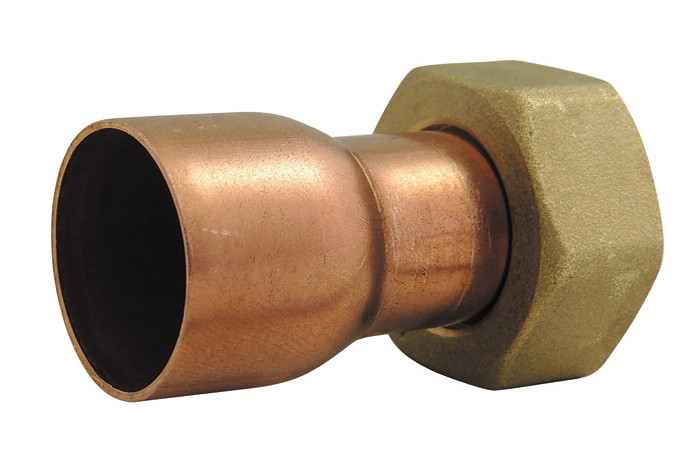

7000L serie

USE

Water and building

| ISO 228-1 | |

| 0 °C / + 70 °C | |

| 16 bar | |

|

COMPRESSION FITTINGS FOR PE PIPES

Multilayer system

MULTILAYER SYSTEM PRESS FITTINGS AND PEXb-AL-PEXb PIPES

USE

Sanitary, Hvac systems.

DESIGN

According to ISO 21003 and NF 545 standards.

MATERIAL

Fitting:

• CW617N brass according to EN 12165 with compliance with 4MS requirements.

• 304 stainless steel sleeve.

• EPDM O-ring.

Pipe:

• PE-Xb/AL/PE-Xb: Cross-linked polyethylene

• Welded aluminum.

| TH (série 25) Ø16 > Ø32 TH-U (série 26) Ø40 > Ø75 |

|

| ISO 228-1 (BSPP) | |

| PEXb-AL-PEXb | |

| -20 + 95°C | |

|

10 bar |

|

|

The NF 545 standard requires a combination of CODITAL SYSTEM tubes and fittings.

|

|

| UNIT BARCODED LABELS | BSP THREADED FITTINGS KIT SERIES |

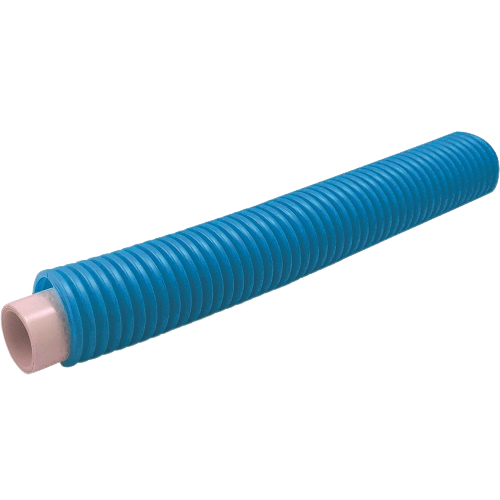

MULTILAYER PIPES

INFO +++

Comparative table of the pipes

| Features | PEXb/AL/PEXb CODITAL SYSTEM® |

PERT/AL/PERT | PEHD/AL/PEHD | PER | CUIVRE |

| Mechanical strength | ++ | ++ | ++ | + | +++ |

| Flexibility | ++ | ++ | ++ | +++ | + |

| Implementation | +++ | +++ | +++ | ++ | + |

| Lifetime | +++ | +++ | ++ | ++ | +++ |

| High temperature lifetime | +++ | ++ | + | ++ | +++ |

| Pressure resistance | ++ | ++ | ++ | ++ | +++ |

| Thermal stability | +++ | +++ | +++ | + | +++ |

| Corrosion resistance | +++ | +++ | +++ | +++ | ++ |

| UV resistance | +++ | +++ | +++ | + | +++ |

| Visual appearance for interiors | +++ | +++ | +++ | + | + |

CODITAL SYSTEM® offers a wide range of pipes in different format

|

|

|

|

| BARE PIPE IN BAR | BARE PIPE IN COIL | CORRUGATED PIPE IN COIL | PRE-INSULATED PIPE IN COIL |

| 255T Ø16 → Ø75 | 255C Ø16 → Ø32 | 255G Ø16 → Ø32 | 255I Ø16 → Ø32 |

Ø

16X2.0

20X2.0

25X2.5

26X3.0

32X3.0

40X4.0

50X4.5

63X6.0

75X7.5

|

|

RESISTANCE ANTI CORROSION |

UV DURABILITY |

The tubes are delivered with caps protecting the ends from deformation and intrusion of impurities.

PRESS FITTINGS

CODITAL SYSTEM® SERIES 25 fitting is based on a TH crimping profile. This is the most common and predominant profile in the multi-layer systems market.

CODITAL SYSTEM® SERIES 26 fitting offers a TH and U multi-profile crimping design.

Bsp threaded

BSP THREADED FITTINGS

| ISO 228-1 (BSPP) | |

| Depending on sealing material. | |

| 16 bar | |

|

USE

General plumbing

DESIGN

Codital brass threaded fittings:

The universal fitting > Page 130

MATERIAL

CW617N Brass suitable for drinking water

|

|

| BARCODED LABELS | BSP THREADED FITTINGS KIT SERIES |

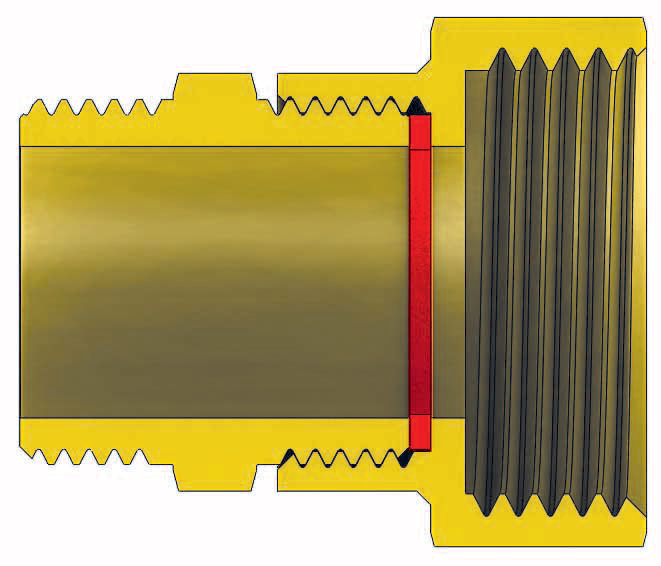

CODITAL BRASS THREADED FITTINGS - THE UNIVERSAL FITTING

BSP THREADED FITTINGS

High quality finishing and machining CNC machining according to strict production process. Reinforced control on each manufacturing step. Meticulous finishing, no burr, no chip

Guaranteed flat gasket sealing. Especially designed for flat gasket sealing*. The gasket is always compressed, including the thinnest ones (thickness from 1 mm). Optimal effective thread lengths. No stop before the gasket compression. Flat and large bearing areas on male and female thread ends

* Our fittings can also be assembled with all other sealing ways (Teflon tape, hemp, glue, etc.).

Malleable iron fittings Whiteheart EN 10242

WHITEHEART MALLEABLE IRON FITTINGS

USE

Water, gas, steam, non-corrosive liquids and gases. HVAC systems.

DESIGN

Fittings are produced according to EN 10242 and ISO 49 standards.

MATERIAL

Material grade : EN-GJMW-400-5 according to EN 1562.

Finishing can be Black or Galvanised (th. 70μm). Both are protected against corrosion to preserve fittings.

TEST

100% of the fittings are leak tested

| All threaded connections comply with ISO 7-1 standard (BSPT), with tapered male end (R) and parallel female end (Rp). Swivel nuts for union fittings comply with ISO 228-1 standard (BSPP). | |

|

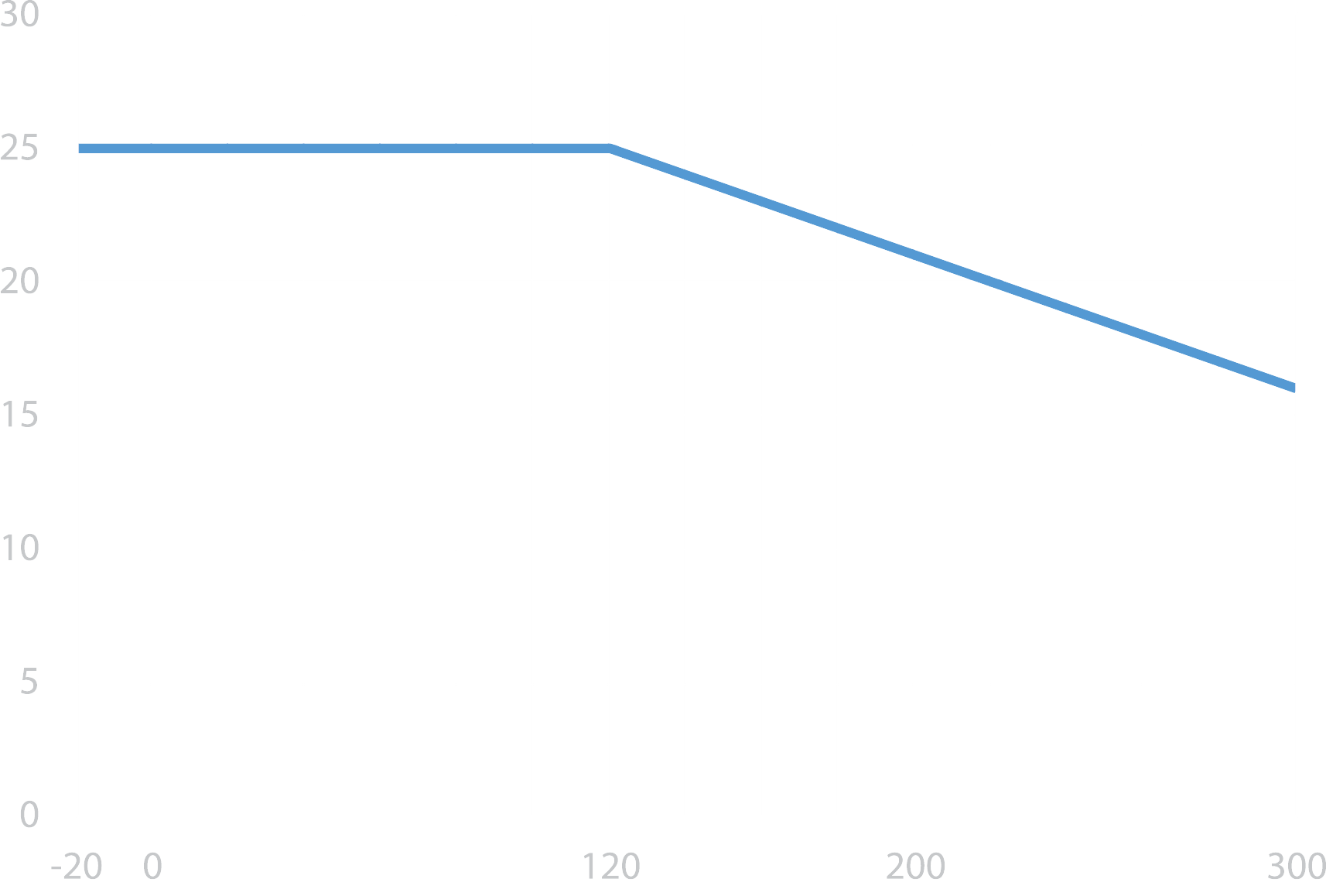

Pressure (bar)  Temperature (°C) Limitation for fitting with fiber gasket: 160°C / Steam 120°C. |

|

|

|

| KIT WHITEHEART MALLEABLE IRON FITTINGS BLACK / GALVANISED |

WHITEHEART QUALITY

= HIGH RESISTANCE TO MECHANICAL STRESS

TIGHTENING - PIPES ALIGNMENT - EXPANSION - PRESSURE - VIBRATION

CRUSHING STRENGTH TEST

|

|

| WHITEHEART | OTHER CAST IRON |

|

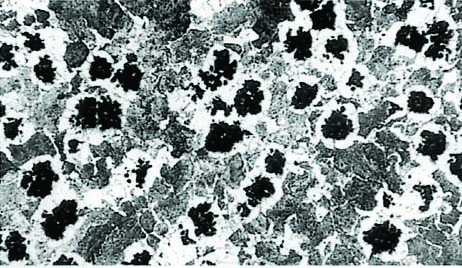

Our fittings are made of whiteheart malleable cast iron, obtained by decarburization. This heat treatment improves the metal elasticity and provides excellent ability to accept deformation under stress without cracking. . |

MICROGRAPHIC OBSERVATION WITH/WITHOUT HEAT TREATMENT

![]()

HEAT TREATMENT 60 H AT 1030°C

This stage consists of removing the carbon from the upper layers of the material (decarburization). Therefore, the mechanical properties of the material are improved, especially the malleability which ensures a better breaking strength.

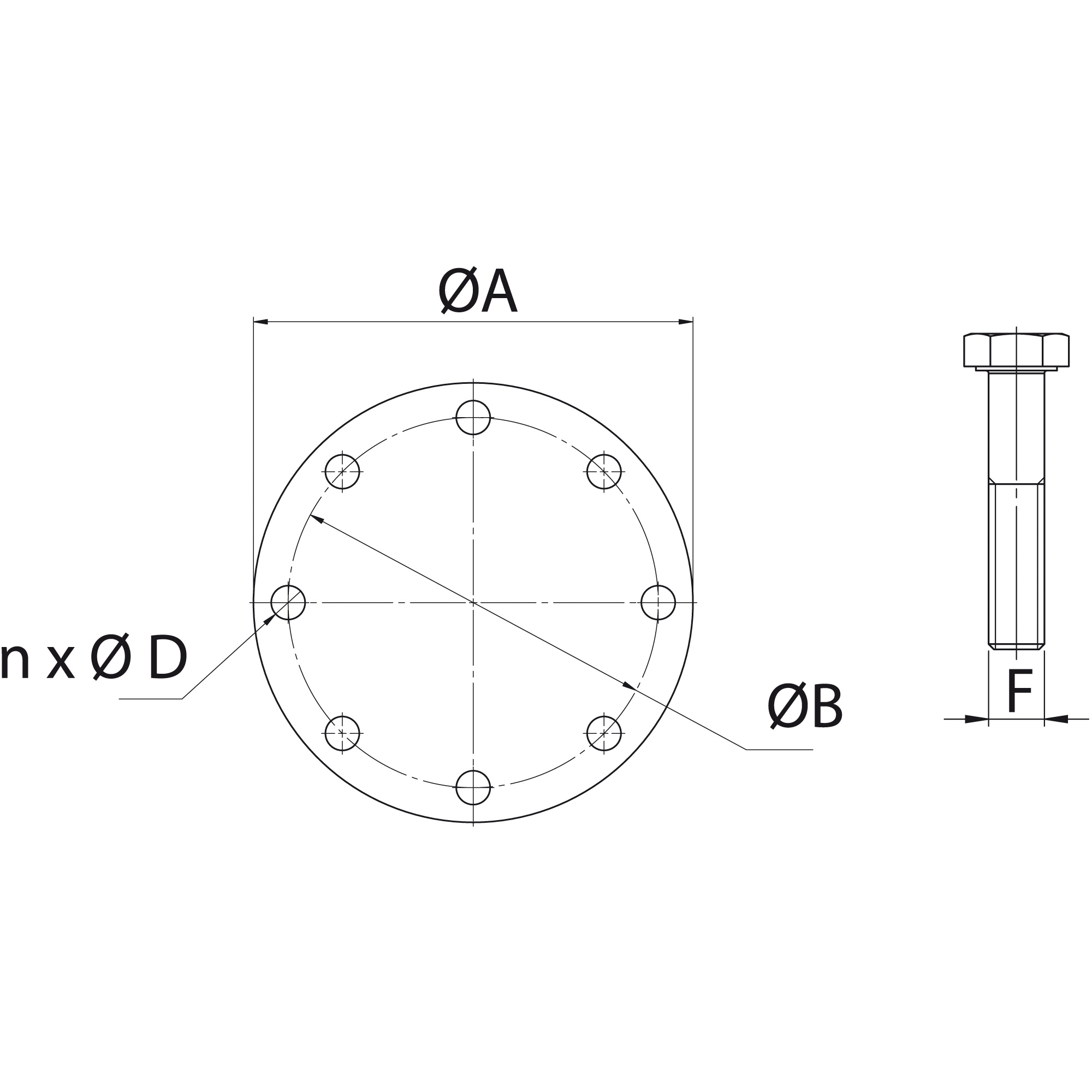

Steel flanges

USE

Universal and suited to all of your industrial application.

DESIGN

CODITAL flanges are manufactured in accordance with EN 1092-1 standard.

It meets the essential requirements of the Pressure Equipment Directive 2014/68/EU.

The EN 1092-1 has been developed based on international standard ISO 7005-1 which include in its scope DIN.

Consequently, our flanges are universal and suited to all of your industrial application.

For further information about the use and the features of our flanges, please refer to the EN 1092-1 standard.

PROTECTIVE COATING “GALVA”

In order to prevent corrosion, we carry out an electrogalvanization on demand (process of applying a protective zinc coating). The electrogalvanized flange price is 50% more expensive than the posted rate.

MARKING AND TRACEABILITY

A marking is made on each flange according to EN 1092-1 standard. It guarantees:

- A complete traceability of raw material used

- A quick identification of the flange

- The provision of 3.1 material analysis certificate according to EN 10204 standard

Certificates 3.1 are available on request, additional fees will then be applied.

MATERIAL

Steel grades :

S235JR

P245GH+N

| PACKING Per unit or wooden box |

|

3.1 inspection certificate acc. to EN 10204 |

MARKING AND TRACEABILITY

| DN | GN 10 | GN 16 | GN 25 | GN 40 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ØA | ØB | n × ØD (F) | ØA | ØB | n × ØD (F) | ØA | ØB | n × ØD (F) | ØA | ØB | n × ØD (F) | |

| 15 | 95 | 65 | 4 × 14 (M12) | 95 | 65 | 4 × 14 (M12) | 95 | 65 | 4 × 14 (M12) | 95 | 65 | 4 × 14 (M12) |

| 20 | 105 | 75 | 4 × 14 (M12) | 105 | 75 | 4 × 14 (M12) | 105 | 75 | 4 × 14 (M12) | 105 | 75 | 4 × 14 (M12) |

| 25 | 115 | 85 | 4 × 14 (M12) | 115 | 85 | 4 × 14 (M12) | 115 | 85 | 4 × 14 (M12) | 115 | 85 | 4 × 14 (M12) |

| 32 | 140 | 100 | 4 × 18 (M16) | 140 | 100 | 4 × 18 (M16) | 140 | 100 | 4 × 18 (M16) | 140 | 100 | 4 × 18 (M16) |

| 40 | 150 | 110 | 4 × 18 (M16) | 150 | 110 | 4 × 18 (M16) | 150 | 110 | 4 × 18 (M16) | 150 | 110 | 4 × 18 (M16) |

| 50 | 165 | 125 | 4 × 18 (M16) | 165 | 125 | 4 × 18 (M16) | 165 | 125 | 4 × 18 (M16) | 165 | 125 | 4 × 18 (M16) |

| 65 | 185 | 145 | 8 × 18 (M16) | 185 | 145 | 8 × 18 (M16) | 185 | 145 | 8 × 18 (M16) | 185 | 145 | 8 × 18 (M16) |

| 80 | 200 | 160 | 8 × 18 (M16) | 200 | 160 | 8 × 18 (M16) | 200 | 160 | 8 × 18 (M16) | 200 | 160 | 8 × 18 (M16) |

| 100 | 220 | 180 | 8 × 18 (M16) | 220 | 180 | 8 × 18 (M16) | 235 | 190 | 8 × 22 (M20) | 270 | 200 | 8 × 22 (M20) |

| 125 | 250 | 210 | 8 × 18 (M16) | 250 | 210 | 8 × 18 (M16) | 270 | 220 | 8 × 26 (M24) | 300 | 250 | 8 × 26 (M24) |

| 150 | 285 | 240 | 8 × 22 (M20) | 285 | 240 | 8 × 22 (M20) | 300 | 250 | 8 × 26 (M24) | 330 | 295 | 12 × 30 (M27) |

| 175* | 315 | 270 | 8 × 22 (M20) | 315 | 270 | 8 × 22 (M20) | 330 | 280 | 12 × 26 (M24) | 375 | 320 | 12 × 30 (M27) |

| 200 | 340 | 295 | 8 × 22 (M20) | 340 | 295 | 12 × 22 (M20) | 360 | 310 | 12 × 26 (M24) | 405 | 340 | 12 × 30 (M27) |

| 250 | 395 | 350 | 12 × 22 (M20) | 405 | 355 | 12 × 26 (M24) | 425 | 370 | 12 × 30 (M27) | 450 | 385 | 12 × 30 (M27) |

| 300 | 445 | 400 | 12 × 22 (M20) | 460 | 410 | 12 × 26 (M24) | 485 | 430 | 16 × 30 (M27) | 515 | 450 | 16 × 33 (M30) |

| 350 | 505 | 460 | 16 × 22 (M20) | 520 | 470 | 16 × 26 (M24) | 555 | 490 | 16 × 33 (M30) | 580 | 510 | 16 × 33 (M30) |

| 400 | 565 | 515 | 16 × 26 (M24) | 580 | 525 | 16 × 30 (M27) | 620 | 560 | 16 × 36 (M33) | 660 | 585 | 16 × 39 (M33) |

| 450 | 615 | 565 | 20 × 26 (M24) | 640 | 585 | 20 × 30 (M27) | 685 | 610 | 20 × 36 (M33) | 730 | 660 | 20 × 39 (M36) |

| 500 | 670 | 620 | 20 × 26 (M24) | 715 | 650 | 20 × 33 (M30) | 760 | 715 | 20 × 39 (M36) | 805 | 730 | 20 × 42 (M39) |

| 600 | 780 | 725 | 20 × 30 (M27) | 840 | 770 | 20 × 36 (M33) | 845 | 770 | 20 × 39 (M36) | 890 | 795 | 20 × 48 (M45) |

| 700 | 895 | 840 | 24 × 30 (M27) | 910 | 840 | 24 × 36 (M33) | 960 | 875 | 20 × 42 (M39) | — | — | — |

*Out of EN 1092-1 standard

Nipples

STEEL NIPPLES

| ISO 7-1 (BSPT) | DESIGN Manufactured according to EN 10241 from welded pipe. |

|

| 20 bar | MATERIALS 195T/S235 |

| PIPES DIMENSIONS |  |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| PACKING Individual plastic bag (< Lg 400). |  |

||||||

|

|

||||||

Sockets

SOCKETS

| ISO 7-1(BSPT) Parallel type (Rp) |

DESIGN |

|

| 50 bar | MATERIAL S235JR |

|

|

KIT STEEL NIPPLES AND SOCKETS |

ISO 4144

STAINLESS STEEL FITTINGS - SERIES 8000

DESIGN

Manufactured according

to ISO 4144 standard.

MATERIAL

Inox CF8M (316)

Stainless steel

| ISO 7-1, (BSPT) Tapered male end (R) and parallel female end (Rp). |

||

| -20 °C / +220 °C |

Pressure (bar) |

|

| 20 bar | ||

|

|

||||

Steel fittings - 3000 LBS

STEEL FITTINGS - 3000 LBS

| Threaded / Welding-threaded / Socket welding |

DESIGN MATERIAL |

Pressure (bar)

Temperature (°C)

|

3.1 inspection certificate acc. to EN 10204 |

Pvc-U pressure fittings PN16

PVC-U PRESSURE FITTINGS PN16

USE

For water supply, irrigation, watering, swimming pool systems, chemical industry, food industry, etc.

SOLVENT CEMENT JOINTING CONNECTION

The solvent cement jointing connection comply with European standard EN 1452.

THREADED CONNECTION

Unless otherwise specified, all the threaded connections are made according to ISO 228-1 standard (BSPP).

FLANGE CONNECTION

Flange dimensions comply with EN 1092-1 standard and are suitable for most of the hydraulic equipments. These dimensions are stated on below table P. 307

The nominal pressure is stated on tables of each product. The working conditions are also linked to fluid temperature according to below table 1

Pressure (bar)

Temperature (°C)

Consult us |

|

KIT PVC FITTINGS |

Compression

COMPRESSION FITTINGS FOR PE PIPE METRIC SERIES

|

PIPES USE |

|

| Our fittings comply with the dimensional requirements of the following standards : EN 712 / 713 / 715 / 911, ISO 3458 / 3459 / 3501 / 3503/ 14236, DIN 8076. Threaded ends comply with ISO 7-1, DIN 2999 and BS 21 standards. These are BSPT fittings, male ends are conical (R) and female ends are parallels (Rp) or conical (Rc) for size 4”. |

|

|

The nominal pressure is stated on tables of each product. The working conditions are also linked to fluid temperature according to below table. Pressure (bar) Temperature (°C) |

|

|

|

|

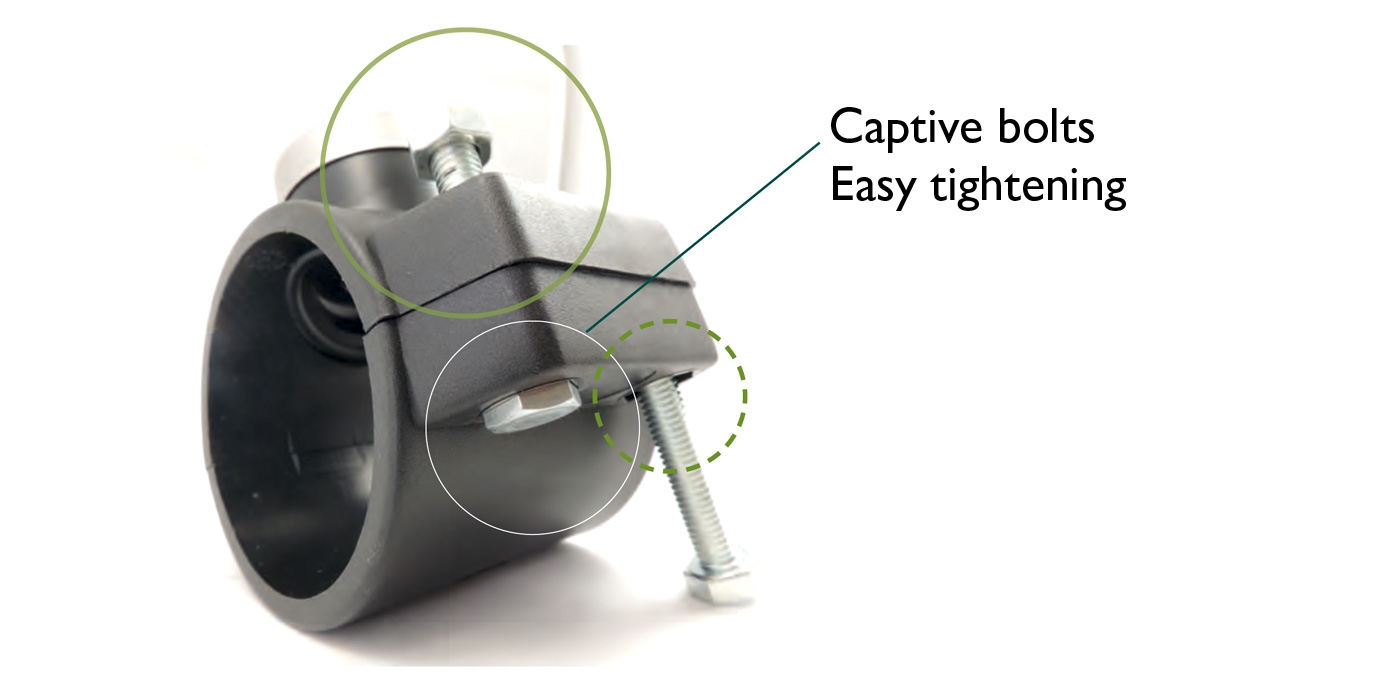

Lubricated and unlosable o'rings. Ergonomic design, easy to tighten.

NEW DESIGN - EASY HDPE PIPE INSERTING

CODITAL improves its compression fittings range with the development of “EASY SLIDE” models, designed to make the pipe insertion easier on big sizes from Ø50 to Ø110. Their design has been thought out to guarantee easy assembling, without prior dismantling of the fitting.

These new products complete a range that is already proven and recognized on the market for its reliability and ease of installation. Nut design improves, with our signature BLUE color.

Hose clamps

SADDLES

|

|

MATERIAL Polypropylene body NBR o'ring Galvanised steel bolts |

PACKING

Individual bag |

|

KIT POLYPROPYLENE FITTINGS |

Ball valves

ICE BALL VALVES

This ball valve is especially recommended for facilities under extreme weather conditions. The innovative design and quality materials offer a high resistance to UV and freezing/defrosting cycles.

Valves – Fluid Control

Valves – Fluid Control

Cast iron valves

Cast iron valves

Measure and control

Measure and control

Sanitary and building

Sanitary and building

Ball valves

Ball valves

Compressed air and quick couplings

Compressed air and quick couplings

Compression

Compression

Multilayer system

Multilayer system

Bsp threaded

Bsp threaded

Socket welding

Socket welding

Copper-brass

Copper-brass

Copper fittings

Copper fittings

Push-fit

Push-fit

Garden hose

Garden hose

Steel flanges

Steel flanges

Malleable iron fittings Whiteheart EN 10242

Malleable iron fittings Whiteheart EN 10242

Steel nipples and sockets

Steel nipples and sockets

Stainless steel fittings - serie 8000

Stainless steel fittings - serie 8000

Steel fittings - 3000 LBS

Steel fittings - 3000 LBS

Malleable iron fittings Blackheart EN 10242

Malleable iron fittings Blackheart EN 10242

Butt-welding steel fittings

Butt-welding steel fittings

Pvc-U pressure fittings PN16

Pvc-U pressure fittings PN16

Polypropylene fittings

Polypropylene fittings

PA / POM accessories

PA / POM accessories

Sealing

Sealing

Flat gaskets

Flat gaskets

Adhesives

Adhesives